Cutting primary energy use with smarter air pre-heating

- Warren Chung

- Oct 7

- 3 min read

Updated: Oct 9

Where steam air heaters fit into the decarbonisation conversation … and why their design matters

Author: Warren Chung

Amid a volatile backdrop of rising energy costs and tightening emissions targets, industrial operators are being asked to do more with less. Oftentimes, this translates to re-evaluating existing processes and identifying opportunities for enhanced energy integration – all in pursuit of reducing primary energy inputs.

For energy-intensive sectors such as power generation and petrochemical refining, the difference between business-as-usual and an optimised thermal system can mean millions of dollars in fuel savings each year. As highlighted by the U.S. Department of Energy, average energy efficiency improvements of more than 20% are achievable, accompanied by significant reductions in primary energy use.

One way to capture those savings is by adopting air pre-heaters in less conventional ways. By using readily available low-grade steam to raise the temperature of combustion or process air before it entering a furnace or heater, operators can realize significantly reduced fuel requirements to reach the process temperature. This not only reduces operating costs, but also directly decreases the plant’s emissions footprint — a double win in today’s energy-conscious environment.

The role of steam air heaters… and why all are not created equal

That’s where steam-to-air heat exchangers come into the picture. By transferring heat from process steam to combustion air, these systems initiate the process at a higher baseline temperature – with the ultimate effect of reducing the workload of burners and other thermal equipment.

In addition to reducing the amount of fuel consumed, pre-heating also lowers the thermal stress on downstream equipment, sustaining performance and equipment longevity.

Here’s where design makes the difference. Tubular steam air heaters, still widely in use, can offer basic pre-heating advantages, but also introduce limitations that undermine potential energy savings. These limitations include:

Propensity to increased failure due to single-point tube breakdowns

Water hammer and vapour shocks that destabilize their performance

Limited corrosion resistance, sacrificing efficiency in the long run

Maintenance cycles that come with lengthy shutdowns

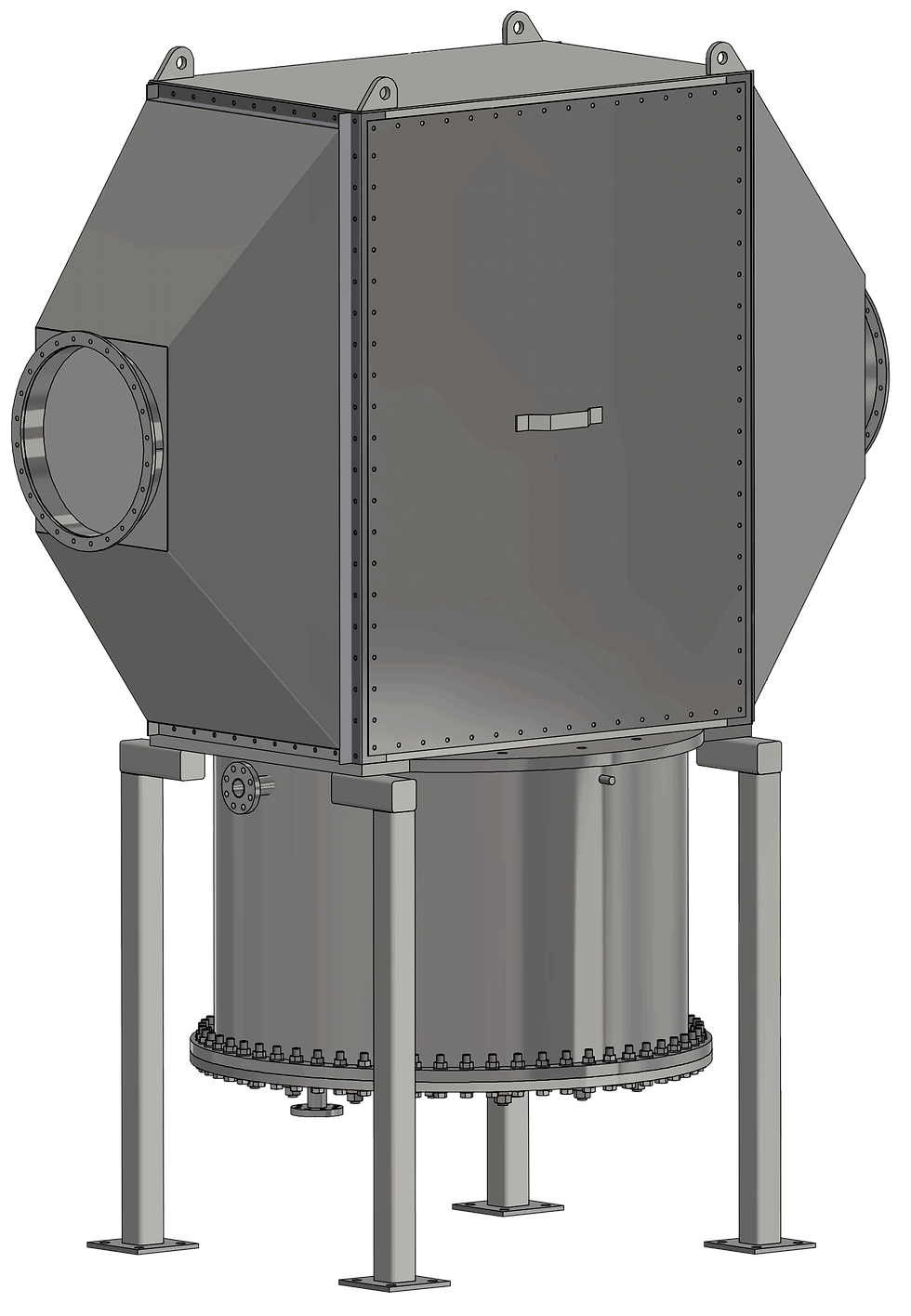

By contrast, heat pipe steam air heaters — like those developed by Econotherm — are optimised for efficiency and longevity. Key benefits include:

Two-phase heat transfer within heat pipes translates to realized thermal conductivities several times greater than metals like copper or aluminium.

Isothermal operation of heat pipes eliminates hot and cold spots, which both reduces internal thermal stresses and allows for tactical temperature prediction/modeling through the equipment.

Independent pipe operation eliminates systemwide shutdowns, enabling plants to retain efficiency gains even in the rare instance of a pipe failure.

Simple, in-situ maintenance prevents extended downtime and keeps systems running at maximum performance.

Real efficiency, real savings

For operators looking to balance the dual pressures of cost control and decarbonisation, steam-to-air heat exchangers represent a reliable and world-tested method of reducing primary energy inputs without disrupting existing processes.

Through the robust and corrosion-resistant design of heat pipe technology, operators achieve not only those temperature gains more efficiently but also sustain them over the long term. That means fewer unexpected outages, lower operating costs and a lower emissions profile. For operators that seek to balance operational competitiveness with regulatory compliance, these are outcomes that matter.

And because they can be integrated into a wide range of industrial settings — from power plants to petrochemical facilities — steam-to-air heat exchangers provide a scalable path to meaningful efficiency gains.

For more information on how Econotherm’s systems support efficiency, longevity and emissions savings, visit our Steam-to-Air Heat Exchanger page. Or reach out to us directly to speak with a member of our team.

Comments